Personal Note

The staff at Prolink want to thank you for your continued support. We sincerely hope this newsletter finds you doing well and hopefully returning to some form of normalcy. We are excited to introduce you to some new features in the software that we believe will be of value to you.

Product Spotlight: AQL Capability added to Prolink

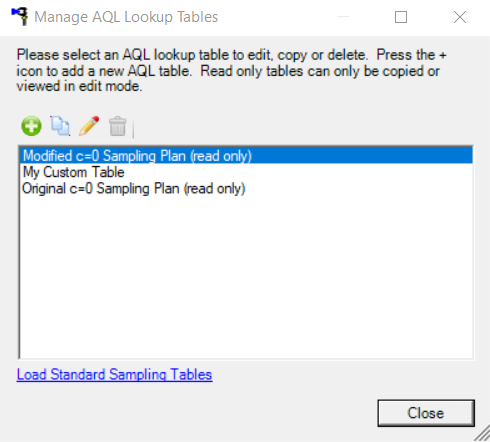

QC-Gage and QC-CALC Real-Time now support AQL based data collection methods. For those who may not be familiar with this standard, the acceptable quality level (AQL) is a measure applied to products and defined in ISO 2859-1 as the "quality level that is the worst tolerable". The AQL tells you how many defective components are considered acceptable during random sampling quality inspections. QC-Gage now can maintain AQL tables to determine for the user how many samples to measure for each characteristic based on the total lot size. The industry standard AQL level tables are included in QC-Gage plus a tool is provided to allow the creation of custom tables. These functions are found in the Tools Menu of QC-Gage and include creating the standard tables or launching a wizard to allow creation of user defined AQL tables.

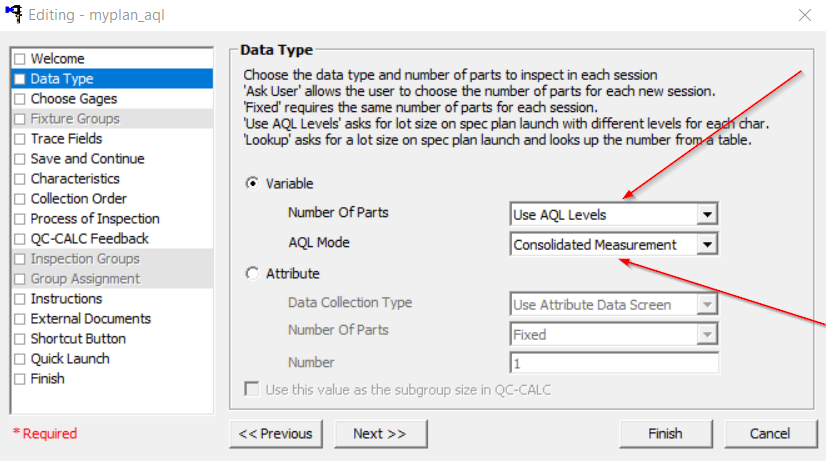

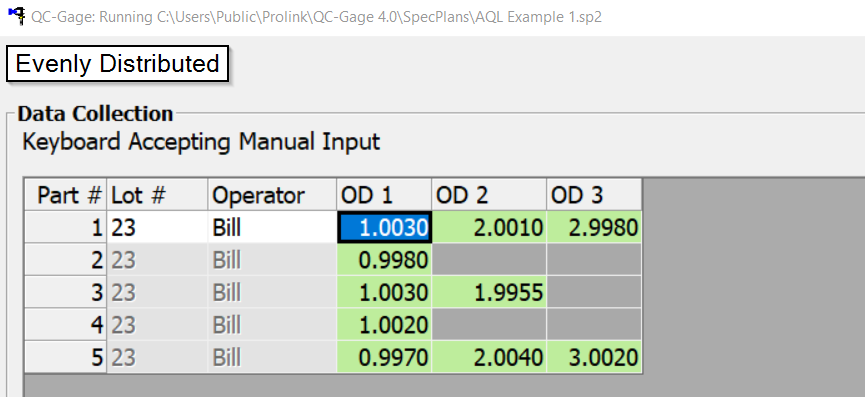

The QC-Gage Spec Plan wizard includes some changes to support AQL level settings. AQL sampling is selected in the Data Type. This now also includes the option for choosing the number of parts. This was formerly in the Number of Parts area. When AQL level sampling is chosen an additional option to choose Consolidated or Evenly distributed measurement (more about this later) for configuration of the entry grid.

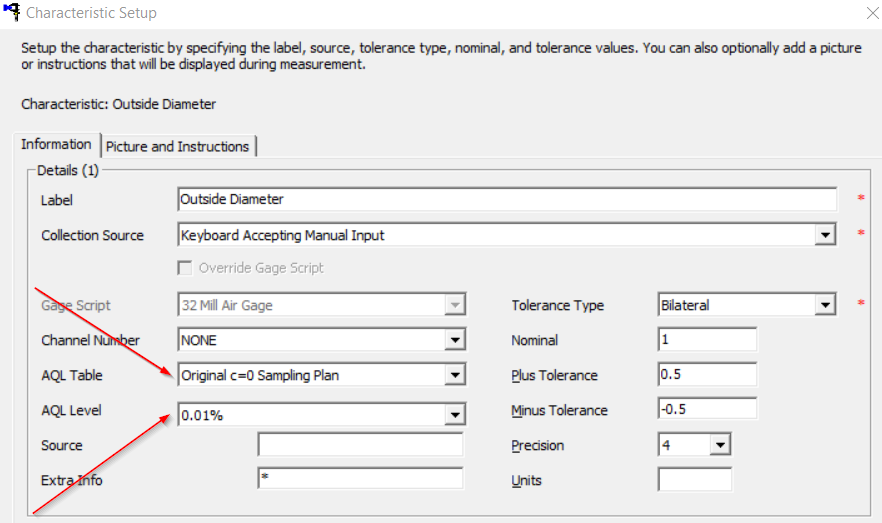

The Characteristics section of the QC-Gage Spec Plan wizard includes two new fields for each characteristic. These fields allow you to set the AQL table desired and level (%) to apply. This will allow each characteristic to be enabled with different sampling quantities as dictated by the AQL level chosen.

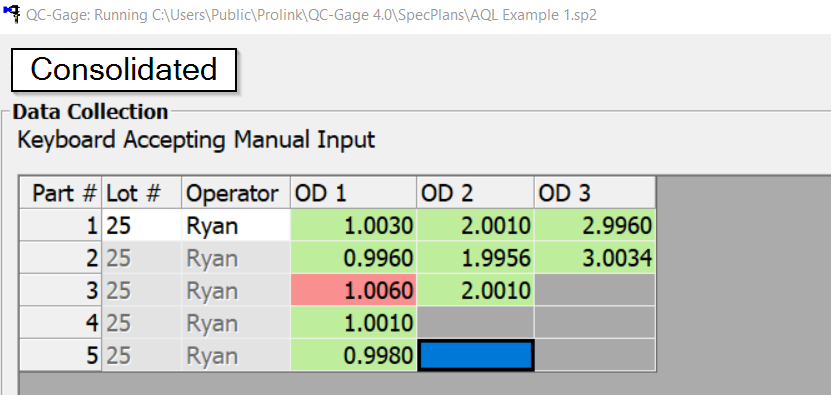

When the QC-Gage Spec Plan is run the operator is prompted for lot size. The data entry grid automatically displays the number of required samples for each characteristic based on the AQL Table and Level (%) chosen in the QC-Gage Spec Plan wizard. The required cells to be populated can be displayed in Consolidated arrangement or evenly distributed across the maximum number of samples for the lot as specified in the setting mentioned above in the Data Type section of the wizard.

When collecting data using AQL sampling method QC-CALC Real-Time automatically tags the data to enable recalling data from a particular AQL lot with any of the Prolink reporting tools and only include data from that lot regardless of the number of samples stored in the database for each characteristic.

Learn More at an Online Demo for GageStation.

Did You Know?

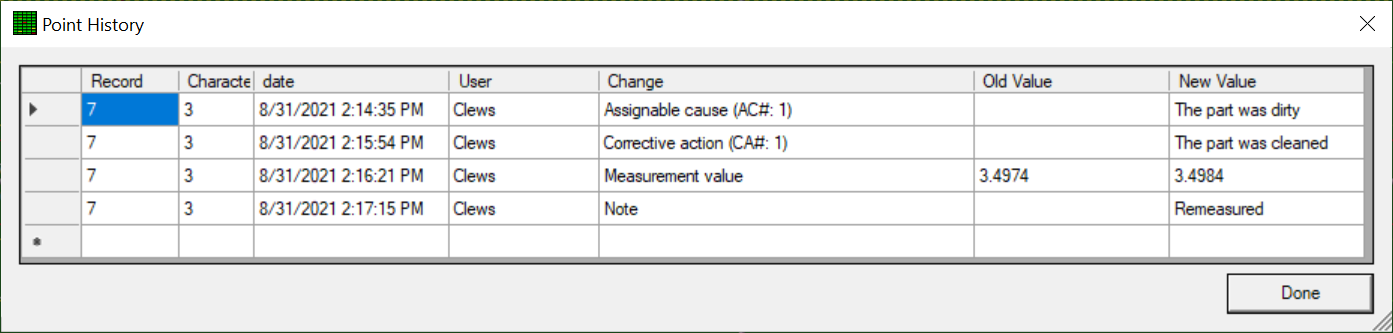

QC-CALC Real-Time can display history of data collection, editing and adding of Assignable Cause, Corrective Action, or notes. Simply right click on any point displayed on the screen. The drop-down menu now includes a Point History choice. Once selected a table is displayed which details the record number, date and time, user, description of entry, and the old and new value (if applicable). This tool is very handy for identifying details related to a specific point of data collected. See below.

Don't Forget

Sign up for our software update emails announcing releases of new versions of our software. Never miss out on a new feature again by subscribing now!

Subscription Preferences

Join one of our Q & A Sessions held twice a week. Our specialist will answer questions on QC-CALC Real-Time, QC-CALC SPC, QC-Gage, or SPC Office Buddy and more. Sign up and learn how to maximize the features in Prolink Software.

Learn More at an Online Demo

Subscription Preferences

Join one of our Q & A Sessions held twice a week. Our specialist will answer questions on QC-CALC Real-Time, QC-CALC SPC, QC-Gage, or SPC Office Buddy and more. Sign up and learn how to maximize the features in Prolink Software.

Learn More at an Online Demo

© Prolink Software Corporation 2021