|

Prolink to exhibit at the Quality Expo 2010

Booth: 1103

April 28-29, 2010

Charlotte Convention Center

Charlotte, NC

Come visit us to see the latest improvements!! |

|

Product Spotlight: QC-CALC 3.3 Released

Prolink is proud to announce release of QC-CALC 3.3.

|

The following are just two of the new features in new QC-CALC 3.3.

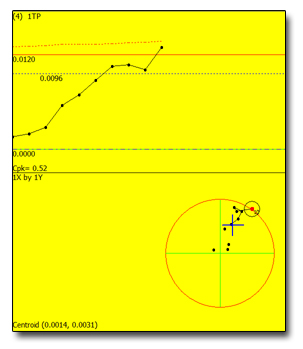

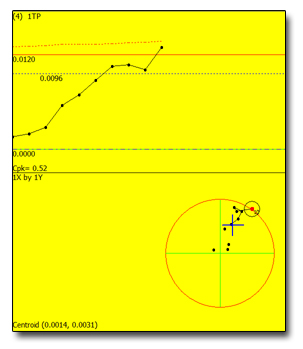

- True Position Charting - The new True Position Plot (pictured at right) automatically calculates the bonus and MMC tolerance. In addition, we calculate Cpk based on the

moving bonus tolerance.

- MultiSource QCC files - QC-CALC 3.3 can now seamlessly integrate multiple data collection

sources into the same QCC file. This means you can measure your parts on multiple

devices and merge the data

automatically.

How To Get It:

Download the latest version of QC-CALC on our website at https://www.prolinksoftware.com.

Want to Learn More?

View the True Position Plot Feature Page >>

View the MultiSource Feature Page >>

|

|

|

|

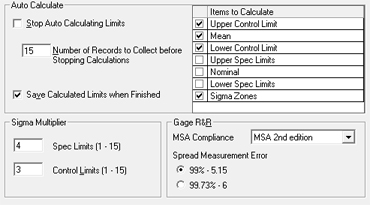

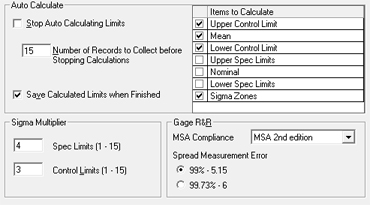

Tip: Need a Cpk of 1.33?? Calculate your limits

The ability for QC-CALC to calculate your limits has been built-in for years. Normally

customers use this functionality to calculate the mean, control limits, and sigma

zones. However, we can also reverse calculate your nominal and spec limits based

on the data you've collected.

We speak with customers all the time who receive tight limits from engineering and

are then told to achieve a Cpk of 1.33 when the process cannot necessarily perform

to such levels. While this doesn't sound very SPC-like, there are certain cases

where it isn't that the process that needs improvement. It's the limits that need

loosening. We won't assist you in your arguments with Engineering, but we will tell

you what your spec limits would need to be if you want to hold a Cpk of 1.33.

|

How To Do It:

- In QC-CALC Real-Time 3.0 or up, go to Tools > Options > Statistical Settings.

- In the area named Auto Calculate, choose which limits you want us to calculate by

checking the options.

- Specify the Sigma Multiplier just below to the left. For a Cpk of 1.33, use 4 as

the Spec Limits sigma value.

- Click OK.

- Choose Tools > Calculate Limits.

The limits you specified will automatically be calculated according to the settings.

PLEASE NOTE: Your new limits are for on-screen purposes only and will not be saved

permanently to the QCC file until you choose Tools > Save Calculated Limits.

To go back to your current limits, perform step 5 again to turn off the calculated

limits.

|

|

How to Get It:

Download the latest version of QC-CALC Real-Time.

Want to Learn More?

Download QC-CALC 3.3 Now >>

|

|